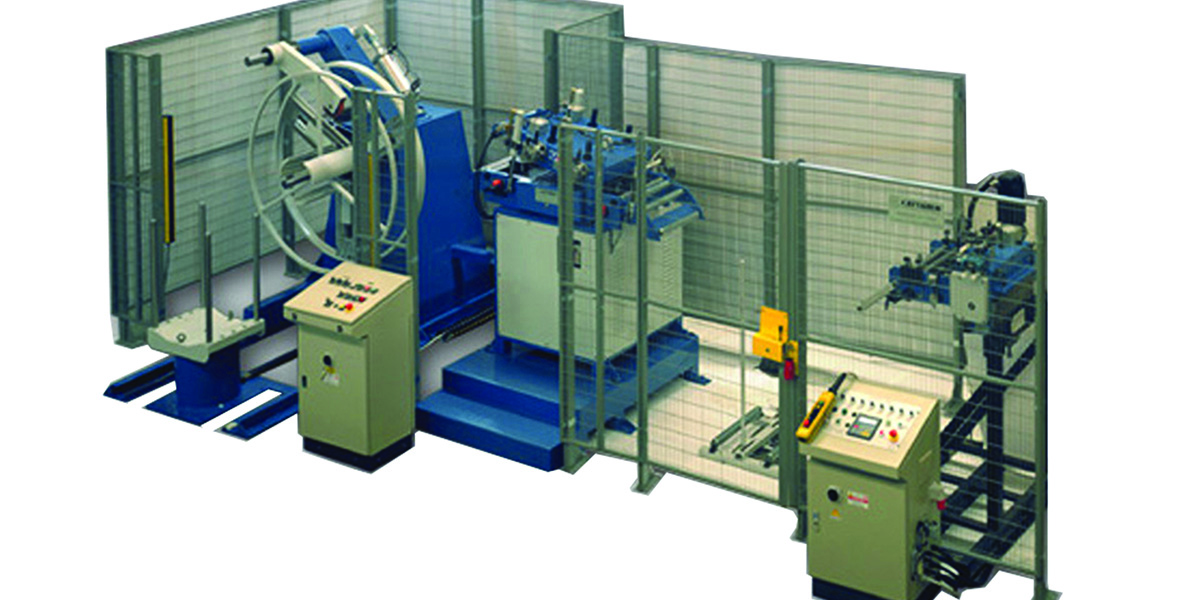

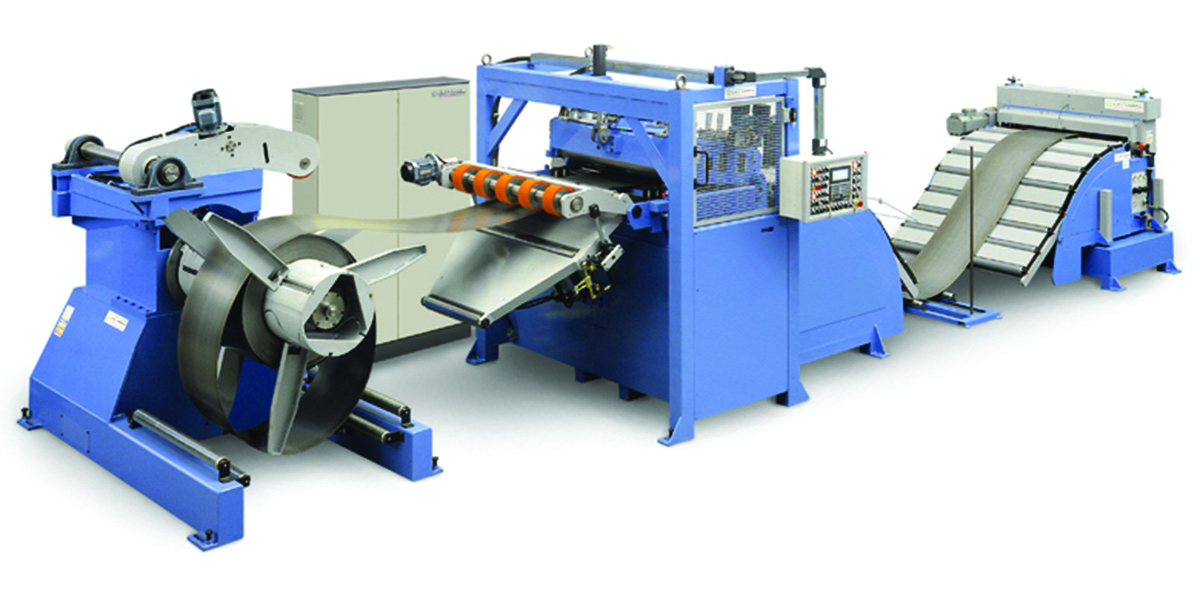

CONVENTIONAL COIL LINE DSF3-1600 UP TO 3 MM THICKNESS

Our Conventional Coil Line DSF3 are the perfect solution to feed the Press for any kind of material without Compromises

because every machine has a dedicate work to do, The Decoiler has to keep the coil closed in order to do not spring out the band, The Straightener run at constant speed (variable and programmable of course) in order to produce a perfect planarity and to supply a loop in smoth way, The Feeder will position the material into the die controlled via Servomotor, cecked by a measure whell with encoder directly on the band and be controlled into the die when possible, The Feeder will be synchro at the Press via an absolute encoder placed on the Press shaft , the DSF3 are suitable for band from 0,7 to 3 mm thickness with all material like Normal Steel, Stainless Steel, Aluminium and Copper , for really delicate material the feeder rolls can be covered by Adiprene.

- Motorised Decoiler (normally single mandrel, optional dual mandrel )

- Motor can be use to introduce the band and to recoil, in automatic mode will worl as brake

- Hydraulic expansion mandrel with 3 jaws at 120° sliding on hardened inclinate support

- Planetary Gearbox and Servomotor connected by adeguate double or tripple chain (depens on model)

- Hydraulic snubber roll motirised to help to insert the band into the Straightener head

- The Decoiler frame can be moved forward/backward by hydraulic cylinder to load the coil

- Loading Chair, normally fixed in front at the decoiler with hydraulic cilinder up/down 300 mm

- Motorised Straightener STR60

- Nr. 4 Vertical side guiding rolls autocentering by screw via hand wheel

- Nr. 5 bottom rolls Ø 50 mm. fixed position

- Nr. 4 upper rolls Ø 60 mm. adjustable by 4 screw jackets with 2 hand wheel

- Pinch-Roll out by 2 rolls pressed by pneumatic cylinders Ø 100 mm

- All lower roll are synchro by gear in oil bath house on board

- Screw gearbox ratio 1:10 with A.C.Motor drive by inverter, direcly mounted on one of the bottom roll

- Loop Control by ultrasonic detector + mass rolls, and control for tide band

- Opening head by 2 hydraulic cylinders for easy band introduction and rolls inspection

- Loader Bridge between Straightener to the Feeder to support the band during intoduction.

- Servo Roll Feeder SRF-100

- Nr. 4 Vertical side guiding rolls autocentering by screw via hand wheel

- Pinch-Roll out by 2 rolls Ø 100 mm. pressed by pneumatic cylinders Ø 100 mm

- Bottom roll direct drive by Precision Screw Gearbox ratio 1:10

- Brushless Servomotor with adeguate size (depens on the band width)

- Measure wheel diam 80 mm with encoder 5000 pulses x 4 = 20.000 pulses

- Support angle with manual adjustment by hydraulic crick (optional motorised)

- NC With Touch Panel 7" with 99 working program with 9 different feed length repetable n. times

- Max feed speed 90 meters/minute

- Position accuracy + - 0,05 mm

- Electric cabinet on pulpit 800 mm near the feeder (optinal big electric cabinet behind and terminal board in front)

- Mobile hand box with 3 meters cable for the manual feed controls

- CE Autocertification and 12 months garantie

Optional extra:

- Motorised and programmable straightening rolls setting with dynamic increment

- Motorised and programmable side guiding rolls

- Motorised and programmable conus rolls in front at the decoiler as band guide

- Dual Decoiler Mandrel

- Safety protection with fixed net behind an safety photocell in front at 1 meter band distance

- Consultancy for press interface (emergency and different signal are necessary)

- Installation and commissioning at the Customer plant

- Annual Maintenance contract after the 12 year guarantie

The conventional lines DSF3 are avaiable in the standard band width 220-330-420-620-820-1020-1320-1620 mm.

The DSF6 lines are suitable for band thickness from 0,7 to 3 mm, 2,5 if stainless steel or high tension material.

and they have CE certificate, Instruction technical Manual in English.