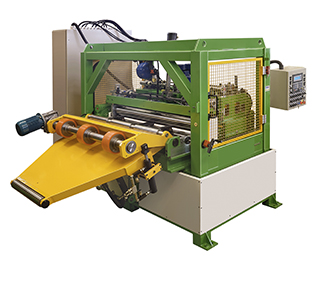

STRAIGHTENER/FEEDERS SSF-80-1600 UP TO 5 MM THICKNESS

Straightener/Feeder able to work with material from 1 to 5 mm thickness

Frame in steel tube electrowelded, roll support by steel plates 30 mm thickness

Rolls configuration by 7+2 rolls diam 80 mm hardened at 62 HRC and grided as mirror

Inlet guide roll made by 4 vertical rolls autocentering by screw and hand wheel, position visualized by digital device

Nr. 4 bottom rolls at fixed position, interaxe 88 mm all connected bt gear in oibath

Nr. 3 upper rolls adjustable by gearbox via hand wheel (optional motorised and programmable)

The lower rolls are connected at Screw Gearbox ratio 1:10 and Brushless A.C. Motor and Servo Driver

The upper rolls are adjustable at the inlet and at the outlet position

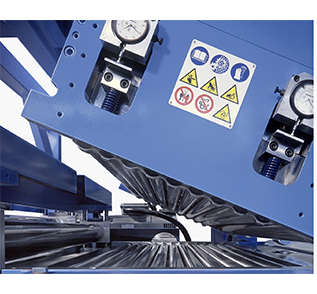

Pinch-Roll out pressed by 2 pneumatic cylinders

Opening head by 2 hydraulic cylinder for easy band introduction and rolls inspection and cleaning

The SSF80 is equipped by a CN with possibility to program 99 programs with 9 variable feed repetable N. times

Measure wheel with encoder reading direct on the band in order to consider even sleeppinng situation

Manual Hand box for thr manual operation

Electric Interface with the Press in order to share the emercency stop signals

OPTIONAL EXTRA:

Inlet lower table with free roll at the end

Upper inlet table with motorised deformation roll, or free roll

Motorised heigh Adjustment + 200 mm

Motorised and programmable upper roll setting with dynamic increment

in order to have a continuos pression increment during the coil consumption

Opening head everyt stroke for total pilot release (up to 70 spm)