SERVO ROLL FEEDER SRF-120

This Roll Servo Feeder can feed material up to 6 mm thickness at Press Running up to 150 SPM

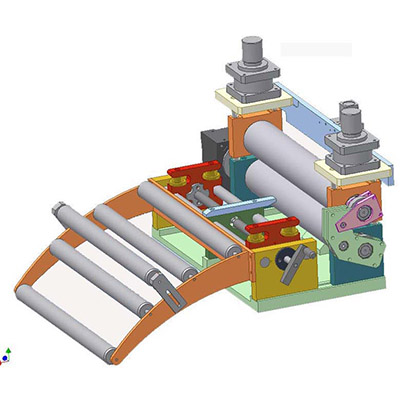

Configuration 2 pulling rolls diameter 120 mm. Hardened HRC 62 and grinded as mirror

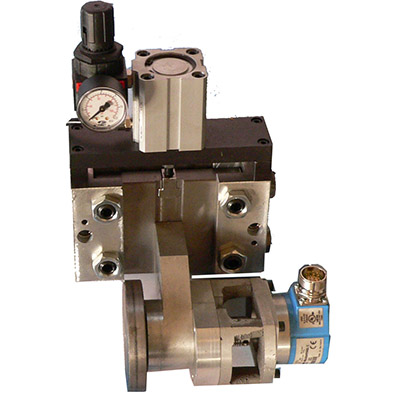

Brusshless Servomotor with screw gearbox 1:15 directly connetced at the lower roll by ring spann

Upper roll synchro by 4 gear wit low gap, the upper roll it is pressed by 2 pneumatic cylinders for band insertion

- Possibility to have pneumatic pilot release up to 150 rpm with pilot angle 50°

- Digital Servo Drive with possible overload 2 time the nominal of the motor for 0,2 minute

- Inlet roll braket at 4 rolls, Nr. 4 side guide rolls autocentring by screw and hand wheel with 20 mm possible offset

- Measure wheel with encoder 5000 pulses x 4 times directly pressed on the band with adjustable pressure

- Standard adjustable support angle by manual crick 160 mm (oprional motorised with 200 mm range)

- The feeder can be made at standard band wide 220-320-420-620-820-1020-1320 mm. Max Thickness. mm. 4

- Max speed 150 metres/minute, Max acceleration 50 metres/sec^2

- Feed accuracy + - mm. 0.04 (using measure wheel)

- Programmable Feed Length from 0.1 mm. to 9 metres

- Electric Cabinet in pulpit wide 800 mm (optional Column 600x2000 with remoted control)

- NC integrate in the Digital Servo Drive with 99 programs with 9 possible different length programmable no times

- Display Touch Screen 6” Standard system Emerson Control Techniques (optional exra price by Siemens)

- Press command by dedicate relay, possibilito to work as Master or by Slave on mixed

- Absolute encoder to be mounted on the Press Shaft for Syncro Press/Feeder (electronic cams)

- Mobile manual commands with 3 meters cable with jog forward/backward Manual/Auto Single feed, Emergency

- OPTIONALS EXTRA PRICE:

- 200 mm Pass line adjustment by screw gearbox and electric motor

- Straightening unit with 5 free rolls diameter 60 mm and fast opening by pneumatic cylinder

- ZIG-ZAG Version to optimize the scrap in the disc coil line