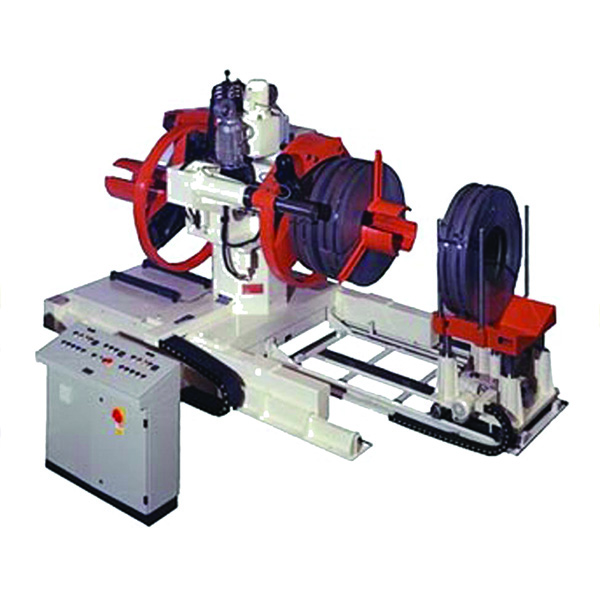

MAGNUM SIZE DUAL DECOILERS

The DECOILER has been specifically designed to undwind coiled materials, Dual Decoiler has 2 Mandrel

They may be used to supply material to STRAIGHTENER or PRESS FEEDERS or PROFILES machines overcoming the drawbacks of conventional DECOILERS.

The DUAL DECOILER optimize the down time at the coil loading, one mandrel work and the other mandrel it is free to be loaded and prepared for the next introduction, so even without the crane ot forklift the coil change will always be ready without loosing production time, this fact it is very important when the crane has to load more than one decoiler .

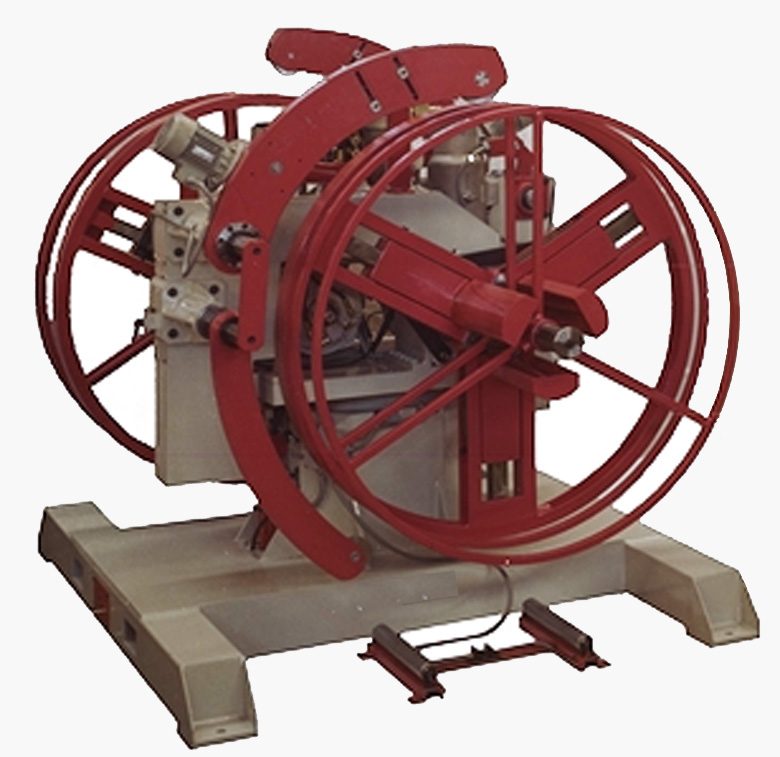

- The mandrel large external coil diameter capacity helps to minimize production downtime

- The main shaft is engineered to support overload with accidental situations caused by mishandling coils during loading, some time the operator do not pay he necessary attention, moving big coil it is easy to overload the shaft

- The planetary gearbox and th A.C. Motor drive by inverter provide a smooth start and stop operations

- The wide expansion range of the mandrel enables all types of coil with inner diameter from 430 to 540 mm.

- For bigger inner diameter it is possible to add extra cover over the mandrel

- The 180° head rotation is motorised, the head turn on big roll bearing commanded by combinated gear box

- When in position the head will be clamp by i big conical pin commanded by hydraulic cylinder and detected

- The hydraulic system olny work when requested by pressostat or manual buttons, to save energy

- Each mandrel has a safety brake disk to stop the decoiler in resonable time during emergency mode

- The magnum size dual decoilers are produced in standard size 3-4-5-6-8-10-12 tons

Particular attention at the design stage or our DECOILER has produced robust, versatile and ergonomic equipments.