COMPACT COIL LINE CDSF12-1600 up to 12 mm thickness

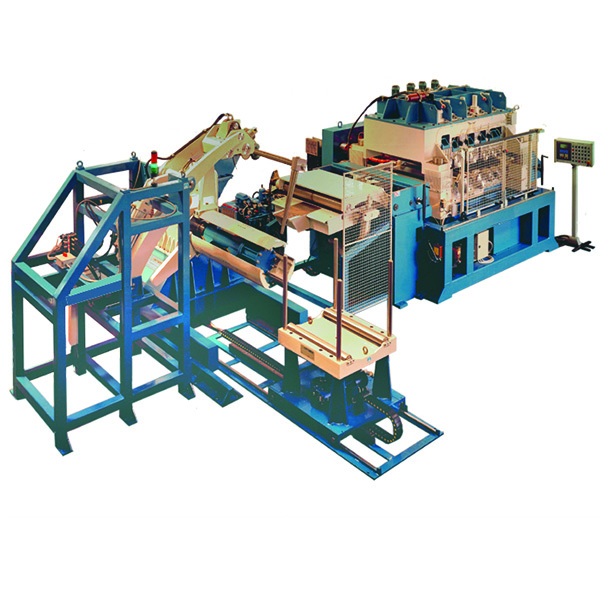

Our Compact Coil Lines guarantee the best compromise for those who do not have SPACE enough to install a Traditional Coil Line in 3 pieces, In the Compact Lines the straightener is equipped by servomotor and NC CONTROL UNIT to add the function of THE FEEDER

Since this is a compromise you can not expect the performance of a traditional line where the simple power supply to the two rollers has a much more favorable dynamics for both the acceleration and the deceleration that for the position accuracy

in particular the Compact lines are little suited to delicate material especially when it has to do with glossy surfaces or that do not bear signs of the rollers or visual mark, are instead very suitable for medium-large even high-strength materials where the thickness control loop of the normal straightening would lead to an exaggerated length:

The line Compact need a space 8 meters, without accessories like introduction tables can occupy a space of about three meters with the boards it takes 4/5 meters (the line space traditional instead occupies from 12 to 15 meters)

The Compact Line consists of a motorized Decoiler at variable speed, with hydraulic and motorised snubber roll and with mobile loading coil car also used as extra bottom pressure arm at the band introduction opertaion.

After The Decoiler is directly STRAIGHTENER / FEEDER , with introduction Tables and Head Can be opened at each stroke of the press for pilot release

The STRAIGHTENER / SSF-300-200-150 it is special made for high tension material up 12 mm thickness

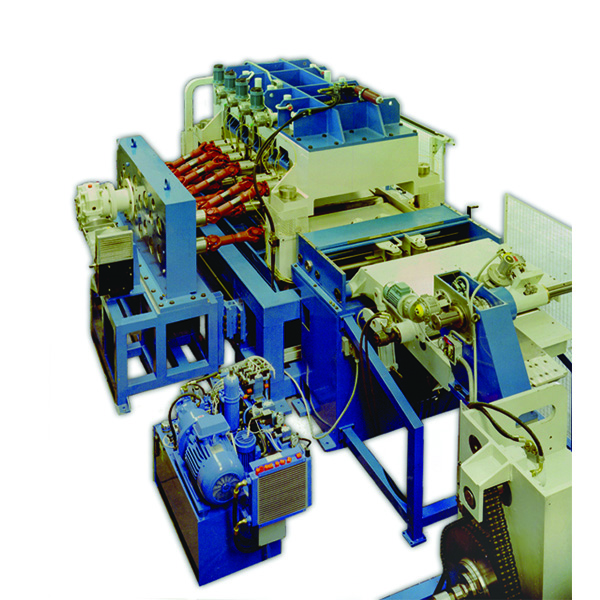

Configuration of the STRAIGHTENER / FEEDER

No. 4 vertical rollers guiding incoming, autocentring ma manual handwheel

Pinch Roll-in with 2 rollers Ø 300 mm. pressed by hydraulics cylinders

Group of 4 Pre-Straightening rollers Ø 200 mm hardened to 62 HRC and rectified ( 2 upper 2 lower)

Group 6 Straightening rollers, Ø 150 mm hardened to 62 HRC and rectified (3 upper 3 lower)

All the lower rolls are synchronized by gears in an oil bath and connected by cardanic shaft

The vertical displacement of the straightening assembly is obtained from 4 Screw Jackets with motorised adjustment,

programmable, dynamic to the decrease of the diameter of the coil is self progressively increasing the pressure to optain the necessary correction from the beginning to the end of the coil (coil memory is very different fom full coil to the end, a corraction must be done to obtain the same planarity)

measuring wheel with encoder directly to band

Vectorial servo motor coupled with worm gearbox 1:30

max speed. 50 meters / minute, feeding accuracy of + - 0.2 mm

Nr. 99 Working programs with repeatable steps No. 9 times

tape width max. 600-800-1000-1300-1600 mm.

strip thickness from 2 to 12 mm with normal and high tensile steel

mobile control panel for manual controls

The machine is equipped Instruction Manual, Safety Manual, CE Certificate

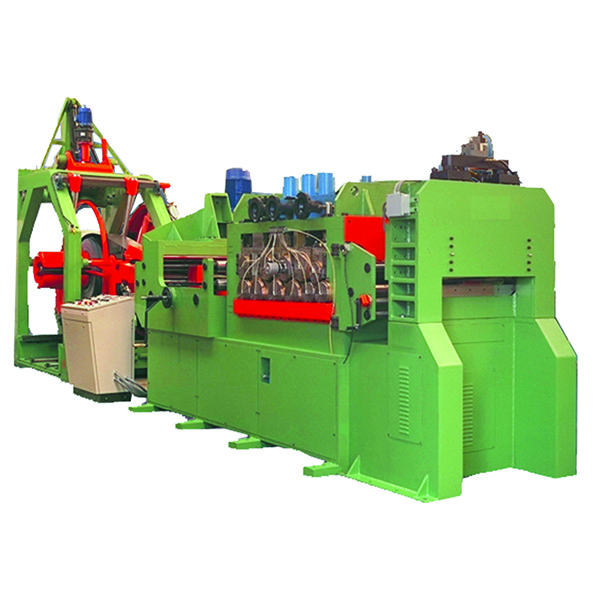

We must remember that this is a compromise dictated by the lack of space, for which performance such as speed, accuracy of positioning and perfect Face milling will never be comparable to those that can be obtained with a traditional coil line in 3 separate pieces, why is obvious:

a) To obtain a perfect smoothing must proceed at a constant speed, here instead it accelerates, it goes a little at maximum speed, deceleration, then in order to release the tape to open the head of the straightening machine, this operation doen not help to produce a perfect planarity.

b) The simple Servo Roll Feeder is a very dynamic device, organized in the lightness, precision, fast, little inertia, the straightener is a machine with more more gear rollers, must also straighten, then larger gearbox and engine, if all goes well traveling to the middle the speed at which can travel a alimetatore two rollers.

c) We must also consider that with delicate band or with such materials Aluminium, Stainless Steel, and especially when you have to ensure quality without signs and without shading on the material, accelerates / decellera moving rapidly then joined at the junction of the rollers definitely will cause marks on superficem that sometimes are not tolerated.

Any way with big thickness over 6 mm the Compact Coil Line it is a good solution because speed and precision are not any more the most important parameters

OPTIONAL EXTRA:

lower inlet table with peeler

Upper inlet table with motorised deformation roll

Adjustable counter-1-2-3-4 lines according to the width